About Silk

Delicate, strong, dyed a thousand colors and woven into the fabric of history. Who can resist the lure of silk?

Discovery and Secrecy Surrounding Silk

B y Karen Selk

More than 4500 years ago, a Chinese empress discovered how to unravel silk cocoons when one dropped into her cup of tea. Until this time, fibre for cloth came from plants (cotton, linen, hemp, ramie) or animals (sheep, goats, camel and yak). No one knew of such a fine and shiny fibre as silk, and no one would have believed it came from the secretions of an insect. As the Chinese and other nations began to travel around the world, they each sent ambassadors bearing gifts to other countries. Silk was the most treasured gift from China, and her intelligent emperors soon realised they had a very important trade commodity. To meet the great demand for silk, the emperors ordered their citizens to pay a portion of their taxes in silk cloth. And to help insure that they would remain an important trading power, the government imposed a law that anyone who revealed the secret of silk production would be put to death.

The mystery of how silk was produced was not revealed to the western world for over 3000 years. One tale is told of two Christian monks who were sent to China to discover the age-old secret of silk production. They returned to Constantinople two years later with silkworm eggs and mulberry tree seeds hidden in hollowed out canes. From here, silk production spread throughout Europe.

What is Silk - from Worm to Worn

Silk Starts With The Worm (which is actaully a moth)

Sericulture

Photo by Karen Selk

Photo by Karen SelkRaising silkworms is called sericulture and is an agricultural-based livelihood that depends heavily on the weather and the attentiveness of the farmer. It is practised throughout Asia, Russia, Turkey and Brazil with China being the largest producer. Workers feed the hungry silkworms fresh, chopped mulberry leaves eight times a day. The silkworms are moved to clean feeding trays once a day.

Some years the silk quality is high, while other years the farmers suffer financially because of poor crops. The price of silk fluctuates with market supply and demand. The economic status of silk-rearing countries also plays an important role in the price of silk. As those countries become more affluent, like Japan, more farmers leave the agriculture industry in search of higher paying jobs. As fewer farmers are willing to carry on the labour-intensive work of raising silkworms, silk is becoming more scarce and costly.

Photo by Karen Selk

Photo by Karen SelkSilk Moths Are Susceptible to Disease

Silk production - called sericulture - had spread to Europe by the middle ages and was an important industry providing royalty with silk colth. But in the early 1800's disease spread through the European bombyx moth population as well as the mulberry trees they depend on. This put silk production in Europe into decline. Then, one the Suez Canel was open importing silk from the east was again popular.

Louis Pasteur saves silk industry

Disease and infection can spread rapidly through a silkworm colony. To combat this problem, each female is placed in a numbered space to lay her eggs and is examined microscopically to ensure there is no disease. If there is any sign of contamination, all the eggs from that female are destroyed. Disease wiped out the European sericulture industry in the mid 1800s. Eventually Louis Pasteur found the source of the disease by testing female moths after they laid their eggs.

Modern Silk Production

Today over half (52%) of the world's silk is produced in China. The second largest production is from India who produces 14%. But silk is an important product for many cultures including Uzbekistan, Brazil, Iran, Thailand, and Vietnam. Japan is often associated with silk but only a small amount of sericulture is done in Japan. Japan is more active in production of silk-based products. (From Wikipedia)

The Chinese word for silk is 'si.'

The Manchurain word is 'sirghe.'

The Mongolian word for silk is 'sirkek.'

Silk produced by caterpillars other than the Bombyx Mori or mulberry silkworm is called 'Wild Silk.'

Central Silk Board, Government of India

Silkworm

Photo by Karen Selk

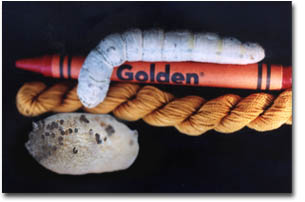

Photo by Karen SelkThe scientific name for the silkworm is Bombyx mori. The silkworm is not a worm at all, but a caterpillar that transforms into a moth. It starts its life in spring as an egg the size of a sesame seed. A silkworm increases its body weight 10,000 times during its life of 28-30 days. If a human baby grew that fast, in two months it would weigh as much as an adult elephant.

The Cocoon

When the silkworm is ready to make the cocoon, it is given a small nook of twigs, braided straw or bamboo. They spin two semi-liquid proteins together at a rate of 30cm (1 foot) per minute while turning 200,000 times in the three days it takes to form a cocoon. It makes a strand of silk as long as 12 football fields which solidifies and becomes a thread when it meets the air outside the silkworm's body.

Photo by Karen Selk

Photo by Karen SelkMetamorphosis to Moth

Inside its cocoon, the silkworm goes into a deep sleep for 11-12 days, while its body goes through a change, or metamorphosis, from silkworm to moth. When this pupa becomes a fully grown moth, it excretes a brown enzyme dissolving a hole in the cocoon. The flightless moth wiggles out and begins searching for a mate. The female moth produces a special scent called a phermone to attract the male moth. One or two days after the male fertilises the eggs inside the female's body she lays 300-500 eggs.

Now We Have the Cocoon

Photo by Karen Selk

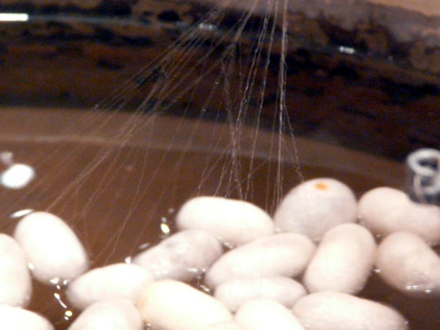

Photo by Karen SelkUnravelling the Cocoon into silk yarn

The silken strand from one cocoon is too fine to make into cloth, so 6-20 cocoons are reeled, or unravelled, at the same time. The sericin sticks the strands together to make a thread the size of a human hair.

A strand of silk is stronger than a similar-sized filament of steel, yet very lightweight.

The left over pupae are rich in protein. They are used as fish food, pressed into oil and people in some countries eat them.

The cocoon is made of a single continuous thread of raw silk around 1 kilometer (2/3 of a mile) long. About 2,000 to 3,000 cocoons are required to make a pound of silk. One pound of silk represents about 1,000 miles of filament. It takes silk from over 2,000 cocoons to produce a single kimono.

Reeled Silk

Reeled, or filament silk is the highest quality yarn and is very white and shiny. First the cocoons are inspected and sorted, as only those with a perfect shape can be used for the reeling procedure.

Cocoons are soaked in warm water to soften the gummy sericin. The silken strand from a single cocoon is too fine to use alone, so individual filaments of 6-20 cocoons are unravelled at the same time, travelling through a very small eye. The softened sericin dries, hardens and binds the strands together to become one thread the size of a human hair. This first stage of silk is very white and lusterous.

The majority of reeled silks is supplied to large industrial looms for making silk cloth.

Spun Silk

The weak filament of the transparent silken envelope remaining from the reeling process, and the damaged, discoloured, or imperfectly shaped cocoons become the raw material for lustrous, creamy coloured spun silk yarn. This cocoon "waste" must first have the sericin removed (degummed) with soap and water. Next, the fibre is cut into uniform lengths and carded to remove short tangled bits as well as the brown pupa inside the cocoons. Combing lays all the fibres parallel in a sliver which is spun into a shimmering yarn. Spun silk is the most familiar yarn made available to handworkers.

Noil or Bourette Yarn

Short fibres containing crushed pupa left behind after making higher quality spun silk are made into noil yarn. The shortness of fibre length results in a lack of lustre and body. This is lower quality spun yarn using the same metric count system as the above spun silk. Noil has the strongest silk odour due to impurities in the yarn. The majority of the smell dissipates after washing, but can return again when wet.

Wild Silk

Photo by Karen Selk

Photo by Karen SelkTreenway's Eri Silk

Karen Selk traveled to India and explored Eri silk production. Read her story here.

Eri silk is from the Assam region of India and has a long history of being used for making the fine cloth that saris are made from.

More Than Bombyx..

The precise shape of the individual silk threads — determined by the shape of the orifice through which they are extruded — is characteristic of the species of silk moth that produced the strands.

[ Reference: ]

Scientific classification of wild silkmoths:

- Kingdom : Animalia

- Phylum : Arthropoda

- Class : Insecta

- Order : Lepidoptera

- Family : Saturniidae

When most people speak of silk they mean the product of the domesticated Bombyx Mori silkworm. Bombyx caterpillers only eat the leaves of the Mulberry tree. Production of Bombyx silk has been exported around the world - where ever the Mulberry tree may be grown to feed the caterpillars.

Wild silks are defined as any silk made from a caterpillar other than Bombyx Mori. There are over 500 caterpillars which produce cocoons but only a few types are used for fiber production. Wild silks are characterized as having a tougher and rougher silk than Bombyx. Wild silks are not white but are often beige or golden in color.

Wild silk is most often associated with India where wild silk has an ancient history. But techniques to demineralize the cocoons is expanding the use of wild silk and it is expected to lead to greater wild silk production in Africa and South America, where the climate is well suited to for wild caterpillars. Silk production is an efficient industry that does not use too much space or water. [ Cite: NYTimes- 2022-05-24 ]

Wild Silk Is An Important Global Product

The Genome of Wild Silk Moths Has Been Sequenced

Visit the online Wild Silk Genome Database

Non-mulberry sericigenous fauna belonging to the family Saturniidae (superfamily Bombycoidea) are mostly wild Silkmoths. In addition to silk fiber production wild silk is studied as an important tools in basic entomological and biotechnological research in various countries.

These are medium to very large in size, and this family includes the largest moths. Adults have a wingspan of 3 to 15 centimeters, relatively small heads, and densely hairy bodies. Larvae are usually very fleshy, with clumps of raised bristles. Caterpillars mostly feed on leaves of trees and shrubs; some cause severe damage. Pupa develops in silken cocoons. Wild silkmoths are reared on wild trees but can also be raised and bred under complete human control.

They complete their life cycle of four different metamorphosing phases, egg, larva, pupa and adult (moths). Of this only larval stage is feeding period. The range of food selection of these insects is wide. Their cocoons are bigger than those of the domesticated silkworm.

Wild silkmoths include tasar silkworm, eri-silkworm, oak-tasar silkworm and muga silkworm. Most of the research and development of technology is confined to China, India, and Japan in Asia.

The Indian Tasar Silkworm, Antheraea mylitta is a natural fauna of tropical India, represented by more than 20 ecoraces. Large quantity of Indian and Chinese tasar cocoons are utilized to produce various types of textiles.

Japanese oak silkworm, Antheraea yamamai is a native of Japan with 31 chromosomes. It is also unique because it contributes to the production of a highly priced silk.

Eri Silkworm, Samia cynthia ricini (n= 13) a multivoltine silkworm is known for its white or brick-red eri silk. It is distributed in North-Eastern part of India. Its other ecoraces (~16) are distributed across the palaearctic and Indo-australian biogeographic regions.

Antheraea pernyi (n=49) is originated in Southern China, dating back to the Han and Wei dynasties. Antheraea roylei (n=30,31,32) is distributed along the Sub-Himalayan belt of India. Antheraea proylei (n=49) is a successful hybrid of the Antheraea roylei with its chinese counterpart.

Types of Wild Silk

Eri Silk

Also known as Endi or Errandi, Eri is a multivoltine silk spun from open-ended cocoons, unlike other varieties of silk. Ericulture is a household activity practiced mainly for protein rich pupae, a delicacy for the tribal. Resultantly, the eri cocoons are open-mouthed and are spun. The silk is used indigenously for preparation of chaddars (wraps) for own use by these tribals. In India, this culture is practiced mainly in the north-eastern states and Assam. It is also found in Bihar, West Bengal and Orissa. [Reference]

| Species: |  For wild Eri silk the subspecies Samia Cynthia Ricini is raised in India. The caterpillars come in a rainbow of blues, greens, yellows and creams with soft tipped spikes on each polka dotted segment of their body. It is the only completely domesticated silkworm other than Bombyx mori. For wild Eri silk the subspecies Samia Cynthia Ricini is raised in India. The caterpillars come in a rainbow of blues, greens, yellows and creams with soft tipped spikes on each polka dotted segment of their body. It is the only completely domesticated silkworm other than Bombyx mori. |

| Food Type: |  Caterpillars are feed the leaves of the Caster Bean. Castor is indigenous to the southeastern Mediterranean Basin, Eastern Africa, and India, but is widespread throughout tropical regions (and widely grown elsewhere as an ornamental plant). Caterpillars are feed the leaves of the Caster Bean. Castor is indigenous to the southeastern Mediterranean Basin, Eastern Africa, and India, but is widespread throughout tropical regions (and widely grown elsewhere as an ornamental plant).But it also feeds on a wide range of food plants such as Heteropanax fragrans, Manihot utilissima, Evodia flaxinifolia, Ailenthus gradulosa etc. |

| Fiber: |  Eri silk is extremely durable, but cannot be easily reeled off the cocoon and is thus spun like cotton or wool. It has some elasticity and is considered more thermal or warmer than other silks. It darker than other wild silks. Eri silk is extremely durable, but cannot be easily reeled off the cocoon and is thus spun like cotton or wool. It has some elasticity and is considered more thermal or warmer than other silks. It darker than other wild silks. |

Muga Silk (Assam Silk)

Assam Silk actually refers to 3 types of silk produced in the Assam region of India - golden Muga, white Pat, warm Eri silk. But Muga Silk is often called Assam Silk because it is so strongly related to the region. Muga Silk is sometimes called the Pride of India.

| Species: |  Anthereae Assamensis - semi-domesticated multivoltine silkworm of the Assam region of India. Anthereae Assamensis - semi-domesticated multivoltine silkworm of the Assam region of India.Muga silkworm, Antheraea assama (n= 15) is a wild silk moth mentioned in literature as early as 1662 BC. It is widely distributed and cultured in North-Eastern India particularly in Assam state. The golden-yellow muga silk is secreted by this semi-domesticated multivoltine species. Larvae fed on mejankori leaves (Litsea citrata) produce a kind of silk known as mejankori silk, which is favoured for its durability, lustre and creamy white shade. |

| Food Type: |  Muga food plants thrive well in sub-tropical areas. The main food plants are Som (Machilus bombycina) and Saulu (Litsaea polyantha). These plants are perennial which makes Muga silk efficient. Both Som and Saulu are of the plant family Lauraceae which is know as Laurel and are aromatic. Muga food plants thrive well in sub-tropical areas. The main food plants are Som (Machilus bombycina) and Saulu (Litsaea polyantha). These plants are perennial which makes Muga silk efficient. Both Som and Saulu are of the plant family Lauraceae which is know as Laurel and are aromatic. |

| Fiber: |   Muga silk is known for its natural shimmering golden color. Muga is considered more durable. It is thought to improve with every wash, and to be very long wearing, often used for decades. Muga silk is known for its natural shimmering golden color. Muga is considered more durable. It is thought to improve with every wash, and to be very long wearing, often used for decades. |

Tussah Silk

There are a couple of varieties of Tussah or Tasar silk. The main distinction is that the worm eats a variety of Oak leaves. Tussah is understood to be the Chinese variety, while Tasar or Tassar is the Indian type. The caterpillar species is closely related and the resulting fiber is very similar.

| Species: |  Antheraea pernyi. Often called the Chinese Oak Moth, or the Temperate Tussah Moth. It lives in less tropical more temperate climates. It is simi-cultivated and can still survive in the wild, unlike the Bombyx Mori. Antheraea pernyi. Often called the Chinese Oak Moth, or the Temperate Tussah Moth. It lives in less tropical more temperate climates. It is simi-cultivated and can still survive in the wild, unlike the Bombyx Mori. |

| Food Type: |  In China, they are fed on plantations of specially trimmed oak trees on the hillsides. The larvae feed on various species of oaks (Quercus spp.). The oaks on which the caterpillars feed are pruned into shrubs 1.5-2 m high on which the larvae are raised. Two annual crops are obtained. The small spring crop is used exclusively as breeding stock for the large autumn crop. The silk of the autumn crop is mostly reeled. Yields average approximately 45 kg/ha of reeled fibre and about 68 kg/ha of spinning fibre [Kolander, 1985]. The city of Dandong, in Liaoning Province has been a center for tussah silk production for two centuries and in 1980 provided about 70 percent of China’s output. Tussah silk production fluctuates; in 1980, 75 000 tons were produced and about 50 000 tons were produced each year between 1987 - 1989 (Peigler 1999). In China, they are fed on plantations of specially trimmed oak trees on the hillsides. The larvae feed on various species of oaks (Quercus spp.). The oaks on which the caterpillars feed are pruned into shrubs 1.5-2 m high on which the larvae are raised. Two annual crops are obtained. The small spring crop is used exclusively as breeding stock for the large autumn crop. The silk of the autumn crop is mostly reeled. Yields average approximately 45 kg/ha of reeled fibre and about 68 kg/ha of spinning fibre [Kolander, 1985]. The city of Dandong, in Liaoning Province has been a center for tussah silk production for two centuries and in 1980 provided about 70 percent of China’s output. Tussah silk production fluctuates; in 1980, 75 000 tons were produced and about 50 000 tons were produced each year between 1987 - 1989 (Peigler 1999). |

| Fiber: |  Tussah is a highly prized fiber. It is said to blend more homogenously with other fibers than does Bombyx moir when used in blends. It's natural color is off-white, but it is often bleached as preparation for dyeing. It does absorbs dye well. Tussah is a highly prized fiber. It is said to blend more homogenously with other fibers than does Bombyx moir when used in blends. It's natural color is off-white, but it is often bleached as preparation for dyeing. It does absorbs dye well. |

Photo by Karen Selk

Photo by Karen SelkCare & Washing Silk

By Karen Selk

Washing Silk

It is mistakenly believed that silk should be dry cleaned. Commercial silk garments are marked 'dry clean only' as protection for poorly dyed goods more than for the silk.

All natural silk is washable if it is treated with proper care and respect.

Strong soaps or detergents are harmful to silk and can effect the dyes. Use a nonalkaline soap such as Orvus Paste, available at feed and tack shops, or an olive-oil bar soap, such as Kiss My Face, available in natural food stores (grate into small pieces and dissolve in water ready for use).

Use a soft, lukewarm, non-alkaline water. To neutralise traces of alkali add a little pure white vinegar to the second-to-last rinse. The final rinse should always be in pure water.

Once the silk has been washed, it can be rolled in a towel to absorb excess water and laid flat to dry. Silk that is worn next to the skin should be washed frequently. The chloride salts and acids of perspiration should not be left on fibres for a long time, they weaken and rot the silk.

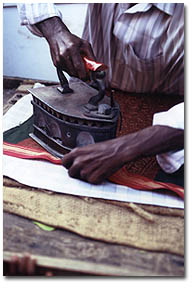

Photo by Karen Selk

Photo by Karen SelkIroning

Handwoven silk fabric rarely needs more than a very light pressing. Yarns are usually substantial and resilient so the fabric shouldn't wrinkle much.

The iron should be set low, like a silk or rayon setting; high heat destroys silk. In most cases you can iron directly on silk. If a metallic looking shine develops use a press cloth between fabric and iron, or iron on the wrong side.

Steam can be used on most silk fabrics. If silk fabric is thin use a dry iron, steam can cause fine fabrics to pucker.

Finishing

Silk may have a tendency to dry "stiff" after washing and ironing due to residue sericin. This is especially true of a fabric right after it is woven or knit. The amount of finishing required for subsequent wearing and washing is much less.

The best time to start the finishing is while the silk goes from damp to dry. Fluff it up or shake it a little two or three times or put it into the dryer on a delicate cycle for a short time.

After washing and pressing "whap" the silk against the soft edge of the ironing board to restore lustre and softness.

Dry Cleaning

Dry cleaning is recommended only if the dyes will bleed. This is especially true of fine prints, iridescent fabrics and silks coming from developing countries where finishing techniques are not exact.

Silk Glossary

- Bell

- A unit of silk caps weighing one kilo. The bell contains silk fibre from approximately 1,600 cocoons. [Photo by Karen Selk]

- Bombyx mori

- The Latin name of the silk producing caterpillar that feeds on mulberry (morus alba) leaves. Its cocoon is the source of fine, white silk. It is reared throughout Asia.

- Bourette Silk (Noil)

- Noil is another term used for a by-product fibre and yarn after higher quality reeled and spun silk are removed from a cocoon. [Photo by Karen Selk]

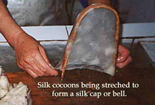

- Caps

- After cocoons have been partially degummed, the fibres are expanded and stretched over a piece of bamboo, bent into an arch shape. Hand spinners use this sort of fibre to make yarn.

- Degumming

- The process of removing natural gum or sericin from silk goods or yarns by boiling in soap solution.

- Denier

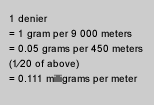

- A unit of measure by which silk yarn is weighed and its fineness calculated.The denier is based on a natural standard—i.e., a single strand of silk is approximately one denier. A 9,000-meter strand of silk weighs about one gram. The term denier comes from the French denier, a coin of small value (worth 1⁄12 of a sou). Applied to yarn, a denier was held to be equal in weight to 1⁄24 of an ounce. The term microdenier is used to describe filaments that weigh less than one gram per 9,000 meters. [ Reference - Wikipedia ]

- Douppoin

- Silk formed by two worms united to spin a single cocoon which is therefore composed of two filaments. They may be reeled into a coarse slubby yarn which is used in the manufacture of pongee, shantung, douppion and other textured silks.

- Eri (or Endi)

- The common name of the Samia ricina caterpillar which eats the leaves of the castor plant (ricinus communis) or kesseru (heteropanax fragrans). This is a semi-domestic silk producing caterpillar reared in Assam, India. The silk is white in colour, with a semi-matt finish.

- Ends per inch (EPI)

- Ends per inch (EPI or e.p.i.) is the number of warp threads per inch of woven fabric.[10][4] In general, the higher the ends per inch, the finer the fabric is. Ends per inch is very commonly used by weavers who must use the number of ends per inch in order to pick the right reed to weave with. The number of ends per inch varies on the pattern to be woven and the thickness of the thread. Plain weaves generally use half the number of wraps per inch for the number of ends per inch, whereas denser weaves like a twill weave will use a higher ratio like two thirds of the number of wraps per inch. Finer threads require more threads per inch than thick ones, and thus result in a higher number of ends per inch. [ Reference - Wikipedia ]

- Filature

- There are several uses of the word 'filature' in the silk processing industry. 1)The establishment for the production of raw (reeled) silk from cocoons. 2) The act or process of reeling raw silk from cocoons. 3) A reel used in drawing silk from cocoons.

- Hankie

- After cocoons have been partially degummed, the fibres are expanded and stretched by hand over a frame forming approximate 10" squares. Handspinners use this form of fibre to make yarn.

- Mommes

- Mommes (mm) are units of weight traditionally used to measure the surface density of silk. It is akin to the use of thread count to measure the quality of cotton fabrics, but is calculated in a very different manner. Instead of counting threads, the weight in mommes is a number that equals the weight in pounds of a piece of silk if it were sized 45 inches by 100 yards. This is because the standard width of silk is 45 inches wide, though silk is regularly produced in 55-inch widths, and, uncommonly, in even larger widths. Silk can also be measured by weight in grams. 1 momme = 4.340 grams per square meter; 8 mommes is close to 1 ounce per square yard or 35 grams per square meter.

- The usual range of momme weight for different weaves of silk are:

- Habutai – 5 to 16 mm

- Chiffon – 6 to 8 mm (can be made in double thickness, i.e. 12 to 16 mm)

- Crepe de Chine – 12 to 16 mm

- Gauze – 3 to 5 mm

- Raw silk – 35 to 40 mm (heavier silks appear more 'wooly')

- Organza – 4 to 6 mm

- Charmeuse – 12 to 30 mm

- The higher the weight in mommes, the more durable the weave, and the more suitable it is for heavy-duty use. And, the heavier the silk, the more opaque it becomes. This can vary even between the same kind of silk. For example, lightweight charmeuse is translucent when used in clothing, but 30-momme charmeuse is opaque.

- Muga

- Muga is one of the Assama Silks. Assam denotes the three major types of Indian indigenous wild silks produced in Assam—golden Muga, white Pat and warm Eri silk.

The common name of the Antherea assama caterpillar which eats the leaves of the Som tree (machilus bombycine) or Soalu (litsaea polyantha). This is a wild caterpillar reared in Assam, India. The silk produced is golden in colour.

- Mulberry

- Common name of the Morus alba tree, which is the sole food of the Bombyx mori silk producing caterpillar.

- Schappe Silk

- This refers to any spun silk yarns (ie: not reeled) which had been degummed by a lengthy and very smelly fermentation process.

- Scroop

- The peculiar scrunching or rustling sound silk acquires when treated with certain organic acids (acetic and formic).

- Shot Silk

- A fabric woven with different coloured warp and weft thread so as to make a tinted or iridescent appearance..

- Tussah (or Tasar, Tussore)

- A wild silk of the Antherea mylitta caterpillar which eats the leaves of the Arjun tree (terminalia arjun), Asan (terminalia tomentosa) or Oak (querus). This caterpillar is raised in the forested regions of China, Korea and India. The silk is honey beige colour. [Photo by Karen Selk]

- Weighted Silk

- The practice formerly used to compensate for the loss of the sericin weight during silk processing. Usually done with tin salts. This caused the fabric to be brittle and wear badly.

Silk News

Silk is such a unique fiber with a long history of human use. Silk is a topic of the past as well as of the future.

Silk Worms Fed Their Normal Diet Plus Dye Produce Vibrant Colored Fiber

We love color. But dyeing silk has its issues.

Conventional industrial silk dyeing involves harsh processing conditions, including high temperature and pH. These processes change the attractive characteristics of silk, weakening it and making it more brittle, and can require further chemical treatments to remove excess dye molecules, add lustre and handle, and to restore the original properties of silk. These processes are complicated and require additional time, money and transportation. Furthermore these processes are implicated in degrading the natural environment; efforts to address the negative impacts of textile dyeing are currently directed towards developing methods to remove toxic dyes from effluents, and this is a costly undertaking involving combinations of biological treatment, chemical coagulation and activated carbon adsorption. Inherent colouration would remove the need for these complicated and expensive procedures. [ Reference ]

In the future the silk worms may simply be fed dye with their regular diet producing colored cocoons and fibers.

Read more:

- Dye-Fed Silkworms Cut Silk Industry's Water Consumption - from Treehugger

- New Silkworm Dye Method Could Help Build Silks With Medicinal Properties - from Popular Science

- Silkworms made to spin coloured silk - from Australian Geography

- A Silkworm's Thread of Color and Hope - from The New York Times

Past efforts to produce colored silk by feeding the worms resulted in colored cocoons which when washed would lose their color. But this new method creates silk that retains the color even after processing.

As explained by

Dr. Tansil said previous efforts to incorporate dye-laced feeds had failed because the dye used had an inappropriate molecular structure, “so it was just passing through the body of the larvae rather than being absorbed to be expressed with the silk. In the past others have produced colored cocoons but these colors come from pigments that reside mainly in the outer layer of sericin,” she said, referring to the gelatinous protein that cements the two fibroin filaments in a silk fiber.

“Sericin is hydrophilic and located at the outer layer, therefore these colors are easily removed upon dissolving in water. Our silk fibroin are still strongly colored even after degumming, the process of removing the sericin, which involves immersing the raw silk in hot water for at least one hour,” she added. [ Reference ]

Silk Genome Sequence Database

Along with silk's ancient relationship with humans, it continues to be an insect and fiber for the future. Recently, a large and diverse collection of genetic markers, including RAPDs, RFLPs and SSRs, have been developed and mapped.

The silkworm genome project experienced three phases. Firstly, a large number of expressed sequence tag (EST) sequences for silkworm multiple tissues have been sequenced and released in 2002. Secondly, 6x and 3x draft genome sequences were independently generated based on whole genome shotgun (WGS) sequencing by Chinese and Japanese groups in 2004, respectively [2-3]. Finally, Chinese and Japanese groups worked jointly and used the merged WGS reads, together with newly generated fosmid- and BAC-end data, to assemble a high-quality genome sequence of the silkworm in 2007.

[ Visit the Silk Genome Database ]Rethinking Silk's Origins - Did the Indian subcontinent start spinning without Chinese know-how?

New findings suggest that silk making was not an exclusively Chinese technological innovation, but instead arose independently on the Indian subcontinent.

Ornaments from the Indus valley in east Pakistan, where the Harappan culture flourished more than 4,000 years ago, seem to contain silk spun by silk moths native to the region. What's more, the silk seems to have been processed in a way previously thought to have been a closely guarded secret within China.

There is hard and fast evidence for silk production in China back to around 2570 BC; the newly discovered objects are believed to date from between 2450 BC and 2000 BC, making them similarly ancient. There have been no previous finds of manufactured silk at sites outside China before about 1500 BC.

"This is the first evidence for silk anywhere out of China at such an early date," says Irene Good of Harvard University in Cambridge, Massachusetts, one of the authors of the study. "It was a complete surprise."

[ Reference: Published online 17 February 2009 | Nature | doi:10.1038/457945a ]

Genetic 'kill switch' Eradicates Female Silkworms For A Better Crop

Transgenic technique developed for mosquito control could improve quality of industrial silk.

The technology used to kill off the female mosquitoes that spread tropical diseases has been turned to a new species — silkworms.

It might seem counter-intuitive to destroy half the crop of such valuable creatures, which can yield a kilometre of silk thread from each cocoon. But male silkworms (Bombyx mori) are much more useful for farmers: they are more resistant to disease, eat less and produce better silk, says Luke Alphey, chief scientific officer at Oxitec, a biotechnology company based in Abingdon, UK. At present, separating males from females is impractical.

Creating male-only silkworms is “something people have been looking at for really a very long time”, Alphey says. Previous attempts, such as by radiation-induced mutation, have had limited success.

[ Reference: Published online 08 April 2013 | Nature | ]

Silkworm Genome Gets Solid Coverage

The most thorough genome sequence data so far for the silkworm, Bombyx mori, have been released by Chinese researchers.

Taken together with sequence data previously released by a Japanese group, the sequence will allow researchers the first comprehensive look into the genetics of a lepidopteran a 160,000 species-strong order including butterflies and moths, which accounts for some 10% of the world's animal biodiversity.

Many of the world's most ravenous plant-eating pests are in this order. Besides possible applications to help the millions of people toiling in the silk industry, agricultural researchers will be scouring B. mori 's genome data, published in this week's Science, for clues on how to protect their plants.

The silkworm has been domesticated over the past 5,000 years, during which time it diverged from its wild and rarely seen ancestor, B. mandarina. Baby worms feed on mulberry leaves until they have spun their silken cocoons. Silk-industry workers then bake or steam them to death, after which the silk is removed.

The process has taken an evolutionary toll. Those fattened individuals that escape their fate turn into moths, but they can't fly and don't live long, says Gane Ka-Shu Wong, a geneticist at the Beijing Institute of Genomics and the University of Washington in Seattle, who co-authored the paper. With no selection for survival features in the adult moth, deleterious single-base pair changes have probably occurred, costing the moths flight as well as their colourful wing patterns. "In that sense, they've really been screwed up," he says.

As a model organism, B. mori has been critical to the development of genetics. Big, flightless and easy to handle, the moths were used by researchers in Japan in the early twentieth century to match or jump ahead of developments in the genetics of the fruitfly, Drosophila melanogaster. But since then, despite some 400 mutant lines in research laboratories, B. mori has largely receded as a model organism. The new sequences could restore it.

[ Reference: Published online 9 December 2004 | Nature | doi:10.1038/news041206-13 ]